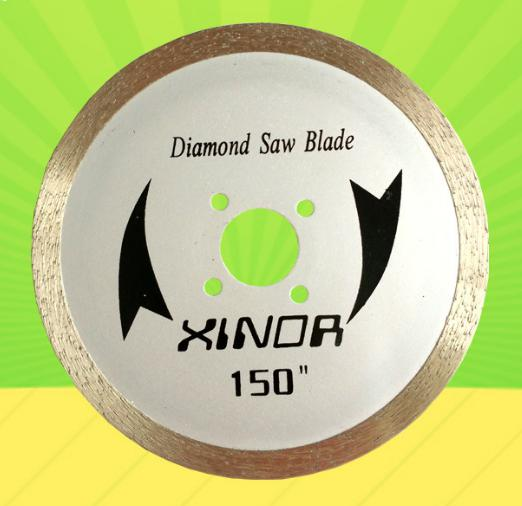

Hantechn@ High Hardness Laser Welded Sintered Diamond Saw Wet Cutting Blades

Embark on a journey of precision and innovation with the Hantechn@ High Hardness Laser-Welded Sintered Diamond Wet Cutting Blades. Designed to redefine your cutting experience, these blades showcase cutting-edge technology. The laser-welded construction ensures unmatched strength and stability, delivering precise wet cuts with ease.

Whether you're a professional contractor or a dedicated DIY enthusiast, these wet cutting blades promise high precision, making each cut a masterpiece for your projects.

|

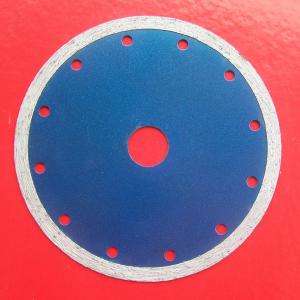

Diamond Wet Cutting Blades |

|||

|

Diameter |

Hole |

technics |

Purposes |

|

100mm 115mm |

20mm, 22.23mm, 32mm, 50mm |

Cold press Hot Press Laser welding |

Formarble, granite, ceramic, concrete |

|

125mm 150mm |

20mm, 22.23mm, 32mm, 50mm |

Cold press Hot Press Laser welding |

Formarble, granite, ceramic, concrete |

|

180mm 230mm |

20mm, 22.23mm, 32mm, 50mm |

Cold press Hot Press Laser welding |

Formarble, granite, ceramic, concrete |

|

250mm 300mm |

20mm, 22.23mm, 32mm, 50mm |

Cold press Hot Press Laser welding |

Formarble, granite, ceramic, concrete |

|

350mm 400mm |

20mm, 22.23mm, 32mm, 50mm |

Cold press Hot Press Laser welding |

Formarble, granite, ceramic, concrete |

|

450mm 500mm Other size viable |

20mm, 22.23mm, 32mm, 50mm |

Cold press Hot Press Laser welding |

Formarble, granite, ceramic, concrete |

Experience the pinnacle of cutting efficiency with our laser-welded sintered diamond saw wet cutting blades. Crafted with precision and durability in mind, these blades redefine the standards for wet cutting performance. Here's what sets them apart:

High-Hardness Diamond Crafting

Our wet cutting blades are meticulously crafted with high-hardness diamonds, ensuring exceptional cutting performance that stands the test of time. The hardness of the diamonds guarantees longevity and precision, making these blades the go-to choice for challenging cutting tasks.

Laser-Welded Technology

The innovative laser-welded construction of these blades elevates their strength and stability to new heights. This advanced technology ensures a seamless bond between the diamond segments and the blade, providing unparalleled reliability during wet cutting tasks. No compromise, only superior performance.

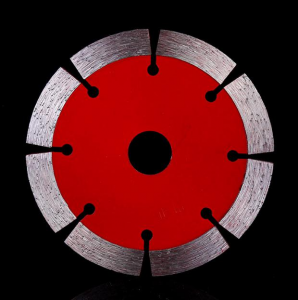

Sintered Diamond Segments

Enhancing the blade's durability and effectiveness, sintered diamond segments are a key feature of our wet cutting blades. The sintering process ensures a robust bond between the diamonds and the matrix, making the blades resilient in the face of demanding wet cutting applications.

Wet Cutting Excellence

Designed exclusively for wet cutting applications, our blades deliver efficiency and cool cutting like never before. The wet cutting process reduces heat generation and minimizes dust, creating a cleaner and more comfortable working environment. Say goodbye to overheating and dust-related challenges.

Versatile Usage

These wet cutting blades are engineered for versatility, making them ideal for various wet cutting tasks across different materials and projects. Whether you're working on tiles, stone, or concrete, our blades adapt to the task at hand, providing consistent and professional results.

High Hardness for Challenging Conditions

The inherent high hardness of our blades ensures resilience and precision, even in the most challenging wet cutting conditions. Tackle demanding projects with confidence, knowing that our blades are up to the task, delivering exceptional results every time.

Professional-Grade Results

Whether you're a seasoned professional contractor or a dedicated DIY enthusiast, our laser-welded sintered diamond saw wet cutting blades guarantee professional-grade cutting results. Elevate your cutting experience with blades that embody precision, durability, and efficiency.

Unleash the full potential of your wet cutting tasks with our advanced blades—where high hardness meets cutting-edge technology for unparalleled performance. Elevate your projects with precision, reliability, and the assurance of professional-grade results.